VPG+

VPG+

Features

Features

The VPG+ software developed by SCS offers unmatched flexibility, control, and reliability for tightening and rework applications:

-

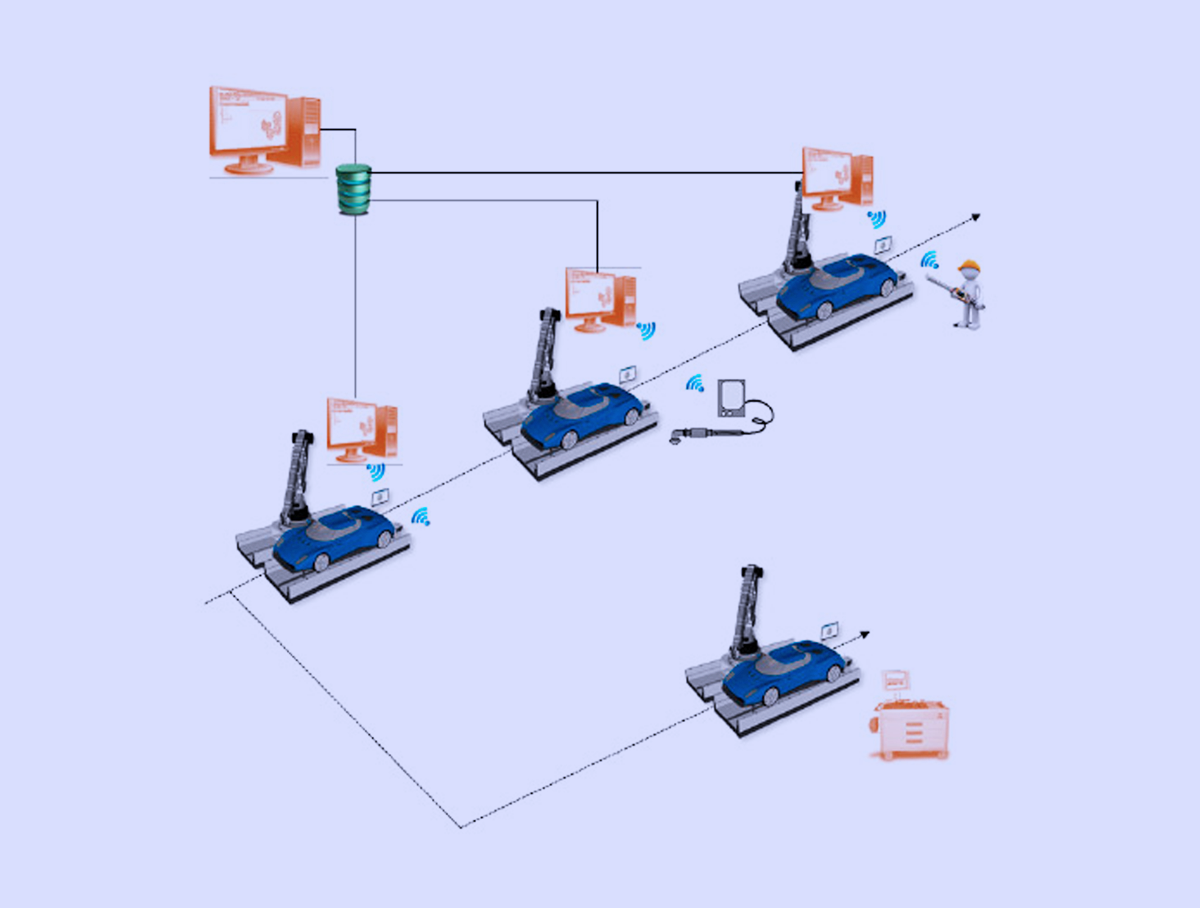

Compatibility Across Nutrunner Brands: VPG+ is compatible with any nutrunner regardless of brand, delivering exceptional versatility and enabling seamless integration across diverse tightening systems.

-

Remote Operations Success: ABS has successfully conducted remote operations using the VPG+ software, highlighting its robustness, reliability, and effectiveness even when operated remotely.

-

Manual & Automatic Operation Modes: VPG+ supports both manual and automatic modes for rework or assembly procedures, giving operators the flexibility to choose the most suitable tightening approach.

-

Visual Cues for Decision-Making: The software provides real-time visual indicators such as OK / NOK images, helping operators instantly determine whether the applied torque meets required standards or if further tightening is needed.

-

Rework Mode for Precision Enhancement: VPG+ includes a dedicated rework mode that allows manual selection of tightening sequences, offering enhanced precision and greater control during corrective operations.

Let's discuss further to get better results

Frequently Asked Questions

free to contact us if you don't get your question's answer in below.